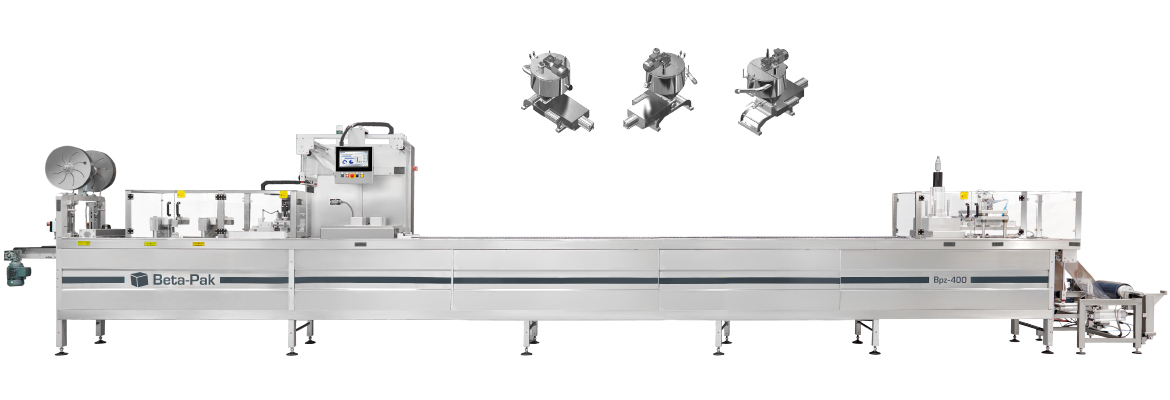

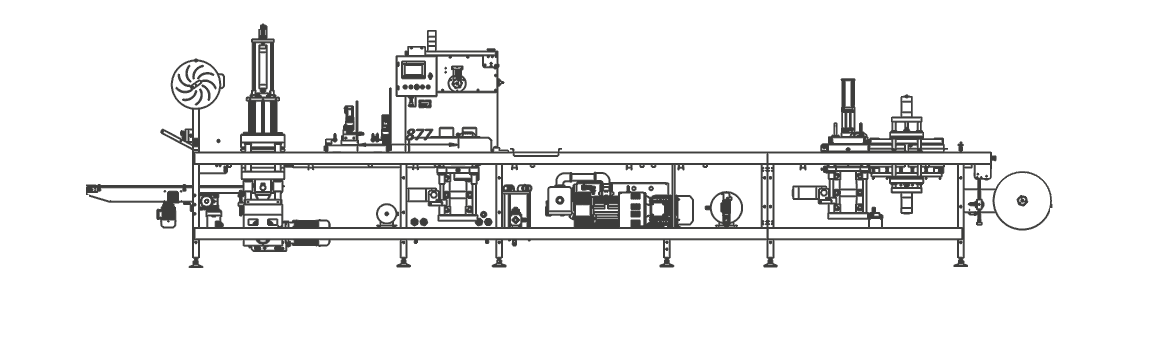

Technical Features

Full Automatic Thermoform Packaging Machine with MAP Application

| Capacity | 6 - 12 cycles/min. |

| Film Widths | 250mm - 600mm |

| Film Thickness | 120 micron - 700 micron |

| Bottom Film | (PVC+PE) / (PET+PE) / (PA+PE) |

| Top Film | (PA+PE) / (ALU) / (PAPER+PE) |

| Step | 200mm - 600mm |

| Reel Diameter | Web - max. 400mm • Lid - max. 300mm |

| Reel Core Diameter | 76mm |

| Shape Depth | max. 85mm. |

| Machine Length | 6.000mm - 12.000mm |

https://www.youtube.com/playlist?list=PLYFkAFNqMcO2Dusd-IO5bx5H7kgvj-hNB